Broadford Works ~ A Dark Satanic Mill

The District name Broadford is reminiscent of a Period when the condition of things was very different from what now exists, for at one time all the District was known as the Broadford Meadowland.

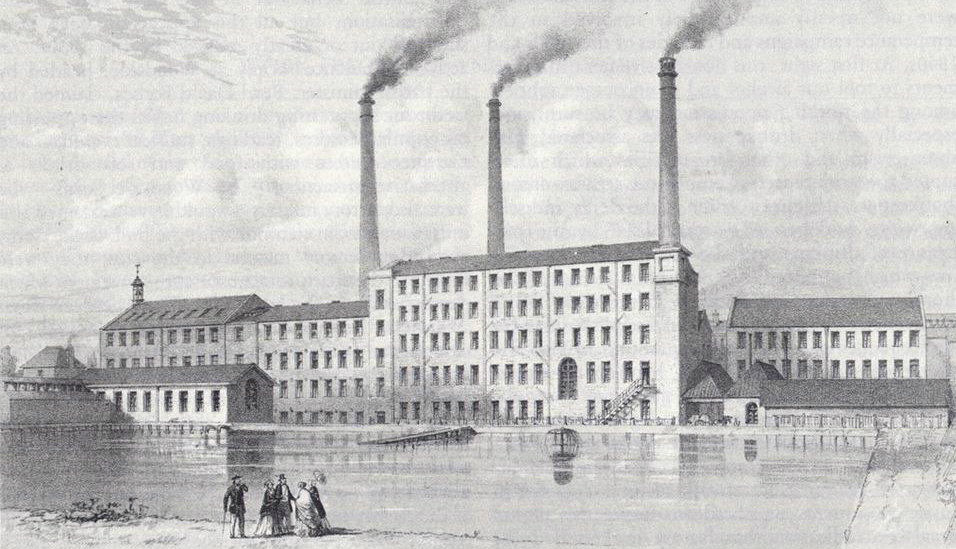

The above Artists View is looking West over the Water Reservior or Cooling Pond required for Steam Powered Flax Spinning and Fed by the Gilcomston Burn; to the Right would have been Hutcheon Street. To the left of the Chimneys the Bellcote with Weather Vane was still extant on the Gable End towards Maberley Street.

Opening in 1808, the Broadford Works became the longest running Iron-frame Mill in Scotland. It was Founded around 1808 as a Flax Spinning Mill. Flax is the oldest Textile Fibre and is used to make Linen. The Flax Fibre is taken from the inner Bark (or Bast) of the Stem of the Flax Plant. Though Flax was grown in Scotland during the 17thC, most Flax would have been Imported from Ireland or Europe. Spinning Flax & Weaving it into Linen would have done on a small scale until the massive Industrial & Scientific advances of the Industrial Revolution. The rise of Mills created stiff competition for small-scale Production and put many people out of Business.

We know very little about the Founders: it was 1st Built for Scott Brown & Co of Angus, which went Bankrupt in 1811. They Advertised the Works Sale in the Aberdeen Journal stating that most of the Machinery was Constructed by Fenton, Murray, Wood & Co of Leeds. Comparisons with other early Mill Buildings suggest that the Iron Frame of the Original Building was an integral part of the Machinery in use. It was Sold to an Entrepreneur, Speculator & Introducer of Jute to the UK, Sir John Maberly MP.

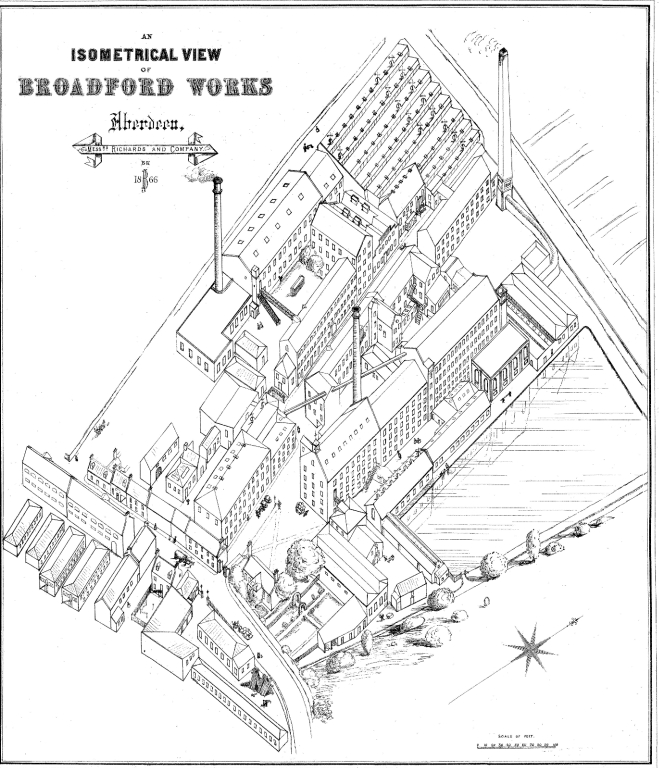

Broadford Works bought by Stephen & John Maberly, began Specialising in Flax Spinning and the Manufacturing of Linen Canvas Goods for Sailcloth, Tarpaulin Covers & Mailbags. The Maberly’s had Linen Manufactories in other Scottish Cities and were successful in Aberdeen, with John Maberly receiving the Freedom of the City. Maberly Street is named after John Maberly. Maberly developed the Works by adopting the 1st Gas Lighting of Industrial Factories in Scotland by Boulton & Watt in 1814-15. The Original Mill is to the right of the Chimney at the Centre of the Isometric Plan by the Cooling Pond Reservoir: the Taller Buildings on either side were added c.1825 (South Mill) and c.1860 (New Mill).The Works prospered & grew, adding a Bleachfield at Rubislaw in 1815. As part of his Contracting Activities Maberly was ‘in the habit of purchasing Aberdeen Linen’ (Checkland 1975, page 308), and in 1811 he took an opportunity to Purchase the Broadford Linen & Sailcloth Factory in Aberdeen. (He may also have established, or bought, a Soap Manufacturing Business in Aberdeen at about the same time.)

Broadford Works is the oldest Iron-framed Mill in Scotland and the 4th oldest known to survive in the World (after others of 1796, 1804 & 1805, all interrelated). The Works was once the largest employer in Aberdeen and the last Textile Mill in the City.

B & W Film 1970 Flax ~ Fibre to Fabric

General Views of Load of Flax being lifted by Crane into top area of Broadford Warehouse in Aberdeen (.59) views of woman splitting the Flax into manageable pieces (1.17) views of Flax pieces going through Hackling Machine (2.49) views of Flax being pulled through Drawing Frame & Spinning Frame (4.33) views of Cone Winding Department and Cones going into Boiling Vat (6.57) views of Warp Winding Department (8.10) views of Strings on Dressing Machine (9.37) views of Drawing Department & Weaving Machines working (11.27) views of Canvas and man checking it and it going through 2 more Machines (12.20) shots of Finishing Department (12.38) views of packs of Cloth being driven away from Warehouse on Lorry (13.13)

Maberly later took on a Partner, John Baker Richards (another London Merchant) and under increasing Financial Pressure, the Partnership dissolved and the whole Business acquired in 1831 by J B Richards and a new Partner, called Leader. A very extensive Linen Manufactory with all the necessary Machinery Houses, Yards etc. Some very fine & powerful Steam Engines are used for propelling the Machinery required in preparing the material, through its different Stages, such as Spinning Weaving etc and gave Employment to about 1,000-Persons, regularly and the Works were still increasing in extent. In 1834 the Works passed to Richards & Co, who had a Bleach Works at Rubislaw and Branches at Montrose. When the Linen is Manufactured here a quantity of it is taken to the Bleachfield at Rubislaw where it is made ready for the Market. Here also are large Vitriol Works and is all carried on by the Proprietors Richards & Co. They became a Public Company in 1898. Richards & Leader continued Manufacturing Linen under the name Richards & Co for about 64-yrs and were the City’s biggest Employers in the 1800s. Unfortunately the Firm got into Financial difficulties with 1,000s of Job Losses. Circa 1898, a Group of Business men formed Richards Ltd to Rescue the Broadford Works from the Financial difficulties of Richards & Co. They did well until Trading became difficult after WW1. Notices were pinned up in the Factory. They told Workers about Holidays (they did not get many). Notices would also tell Workers that they were going to be put on “Short time”. This meant there was not enough Work. So they might only work a few days a week. Richards & Co, from 1892-1921. Richards was a Textile Factory. It produced Thread & Cloth. Another Committee of Persons came forward to save Richards from Closure and from 1934 the Company enjoyed a considerable measure of prosperity.

In spite of his intense Parliamentary Activity, Maberly continued as an Entrepreneur. This would be his undoing. His Factory in Aberdeen, Weaving Jute & Linen, was suffering from the excessive charges Levied by the Scottish Banks. In 1818 he opened a Bank of his own, halving and then quartering the cost of transferring money between London & Scotland. The Scottish Banks were furious, and determined to bring him down. They succeeded, and in 1832 he was made Bankrupt and moved Abroad to avoid the risk of Imprisonment for his Debts. Some later time he Settled in Amiens, a French Industrial Centre striving to catch up with the British Lead in the production of specialty Textiles. With Local Entrepreneurs, he set up a Joint Stock Company, then still a rarity both in France & England, with himself as Managing Director. He introduced Linen Spinning to the Region, building a Large Factory equipped with the latest English Machinery that had to be Assembled Locally with expatriate Labour to avoid British Export Restrictions. The Business was in rapid expansion when he died in 1839. His Memorials are a Maberly Street in Aberdeen and a Rue Maberly in Amiens.

Messrs Richards & Co, on hearing of the success which had attended the attempts of Messrs Hadden & Sons with their Artesian Well, began to Bore, and after cutting through 18-ft of Moss & Black earth, 14-ft of Gravel & small Stones, 4 or 5-ft of Reddish Clay, and, below that, about 6-ft of loose Sand & Clay, they reached the Rock, through which a Bore of 8-ins dia was driven to the depth of 132-ft, making 175-ft in all from the Surface. The Rock was of variable hardness, but mostly Granitic. At the depth of 115-ft, a layer of Sand was met with, accompanied by much Water, and there is reason to believe, that the principal supply of Water which was obtained came from this Bed of Sand. Below this the Rock was very Hard. The Boring was continued for 60-ft further, but without any change in the nature of the Rock, or any notable addition to the quantity of Water. The Spring rose to the surface of the Earth, and flowed over in small quantity, but on putting in a Pump, the supply was found to be equal to about 45-gals per min, and of excellent quality, being, though not absolutely Soft yet not by any means materially Hard.

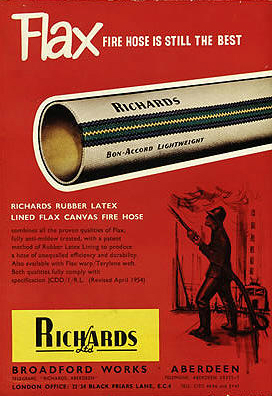

The Linen & Jute Manufactory known as Broadford Works, of Richards Ltd produced Canvas Tarpaulins and as a particular specialism, Fire Hoses. Latterly man-made Fibres for Carpet Yarn etc had replaced Flax. Among Richards’ most famous Products were Fire Hoses. The Hose Pipes were Tested & Dried in the 2-Cylindrical Towers (1-Brick, 1-Concrete) on Site – a distinctive part of the City’s Skyline.

Hose Manufacture – inside Broadford Works, Aberdeen, showing mostly Female Workers on Factory Floor Supervising & Operating Weaving Machinery; Metal Wire is wound over Ends of completed hoses; Male workers Examine the inflated Hose for imperfections; close-up of man operating the Air Pump; c/u Pressure Gauges; men on Scaffolding construct Concrete Chimney and move Reinforcing Rods; elevated shot over Broadford Works towards construction.

Richards Ltd were also leading Spinners & Dyers of Fancy Yarns supplying Europe with Yarns for Knitwear & Textile Furnishings. Heavy Textiles eventually gave way to Carpets, Curtain Materials and Wools for the most exclusive Italian Knitwear as well as for Stores such as Littlewoods & Marks & Spencers. Richards operated a thriving Business from the Site, Employing over 3,000-people at the Peak in the early-20thC, and claiming it the Title of the Largest Single Employer in Aberdeen.

Jute Winder: Jute Mill Worker who wound the thread on Weaving Looms

A large & interesting group of Buildings, the most striking being a 4-Storey, 15-Bay windowless Brick Flax Store with Castellated Central Tower & Corner Turrets. Built in 1912 (see date plaque at NE end), a very large, 4-Storeyed, Red Brick-built Flax Warehouse, much of the Brick emanating from the Seaton Brick & Tile Works in Aberdeen. Several features of the Building are of note. Each of the 4-Storeys are divided into large Compartments, 3-Bays wide. Access to the Compartments was achieved via external Gantries on the NW Facade of the Building, External Hoists lifting Flax to the appropriate Level as desired. In addition, there was a Stone Spiral Staircase in the Turret at the SW Corner of the Building, and what was thought to be one of the oldest Electrically-powered Hoists in the UK housed in a similar Turret at the NE Corner. No Internal access between Compartments was possible, probably as a Fire Precaution. The Internal Frame of the building is Ferro-Concrete, the Floors, Columns & Roof all being Reinforced Concrete (Hennebique System), but the dividing Walls being common (extruded) Red Brick. The Concrete Frame tapers, the Columns becoming thinner within the Upper Floors of the Structure. The Concrete Roof is covered with Asphalt, and at the time of visit, the Machinery for the External Hoists had been dismantled. Features at Roof Level include a large Crenelated Water Tower containing Water for the Fire Sprinkler System, and the Domed Tops of the 2-Turrets, both with Wind Vanes & Lightning Conductors.

The earliest part appears to be a handsome 4-Storey & Attic Granite Block with a Bellcote, modified by the addition of a Brick Water and Stair-tower. There are three other large Brick Ranges, 2-Granite Flax Stores, and a tall Square-section Brick Chimney, built in 1864. The Company made permanent changes to the Aberdeen Skyline with the 1st of the 3-Tallest Structures on the Site in 1862-1864 when they Built the Brick Square Chimney at the North West Corner. Additional Weaving Sheds, Flax Warehouses, Joiner Workshops, Boiler Houses & more would all be Built at the time of Operation & Expansion by Richards Ltd, including a complete re-Roofing of the 3-Main Mills in 1922-1923. The 2nd Tall Structure, the Red Brick Tower, was initially used for the Extraction of Dust. Jute Fibre is also known as Hessian or Burlap. During the 19th & early-20thCs, Jute was indispensable. Its uses included: sacking, ropes, boot linings, aprons, carpets, tents, roofing felts, satchels, linoleum backing, tarpaulins, sandbags, meat wrappers, sailcloth, scrims, tapestries, oven cloths, horse covers, cattle bedding, electric cable, even parachutes. Jute’s appeal lay in its strength, low cost, durability & versatility. Richards had 2-Factory Sites in Aberdeen. One was Broadford Works on Maberly Street, the other was at Garthdee on the North Bank of the River Dee. Later it opened a Factory at Granitehill.

In this day & age, it’s hard to imagine the working conditions. Everybody would be covered in Dust or what was referred locally as ‘stour’, clogging eyes, mouths & noses. The noise of the Machinery created an ever-present, ear-splitting din, with the result that many Workers went Deaf. Women outnumbered men 3 to 1 in the Mills, an imbalance in the Labour Market that gained the term Jute Mill for a Whore House. It created a unique & tough breed of women, born out of being the main providers for the Family. The Mill Girls were noted for their stubborn independence. ‘Overdressed, loud, bold-eyed girls’ according to one Observer and often ‘roarin’ fou’ with drink – characteristics that caused consternation among the ‘gentlefolk’ of Aberdeen. Working alongside the women would be 1,000s of children. Again they commanded only Low Wages, and being so small meant they could pack the Machines closer together. Children under 9 would Work as ‘pickers’, cleaning Dust from beneath the Machines. Health hazards were unavoidable. The heat, dust, grease & oil fumes caused a condition known as ‘Mill Fever’, which would lead to respiratory diseases like Bronchitis. There was always the risk of Accidents with the Machines, Graphic descriptions of which were common reading in the Local Newspaper

Leslie & Hay, Joiners, Stair Rail & Windsor Chair Manufacturers, Hutcheon Street West c.1886

Frances Fowler (Nee Sinclair) worked at Broadford’s after WW2 and it was a disgusting, smelly, choking atmosphere to work in and despite that, it Employed many Cigarette Smoking women – She came home coughing & stinking of Jute which clung to her like a halo & permeated her Clothes. A very dusty Environment and they had to improvise methods to keep the Dust out of their Lungs with Headscarves as Mufflers – Stinking Headscarves at that because of the raw Jute Dust from Carding Machines. As a former Broadford’s Worker she died of Emphysema due to inhaling Industrial Dust and her lifetime Socially Induced Smoking Habit.

Froghall Road. Aberdeen Jute Works

When weemin were wrochtin roon o’ the clock

At the Jute Works or Broadford’s auld Mills,

They’d set aff wi’ a shawl and a kwite owre their frock

To try to get owre a’ their ills.

By gaun ilka pay-nicht alang Cassey-eyn

To buy there o’ mair than ae size:

Sae tasty as kitchie, het, sappy & fine –

Jist ane o’ John Bendelow’s pies.

Penned by Lord Provost George Stephen

From 1930’s John Bendelow’s Pie Shop was in the Spital area. It continued to be run by the Bendelow Family until around 1960.

Oh, dear me, the Mill’s gaen fast,

The puir wee Shifters canna get a rest,

Shiftin’ Bobbins coorse and fine,

They fairly mak’ ye work for your ten & nine (10/9d)

Oh, dear me, I wish the day was done,

Rinnin’ up and doon the Pass is nae fun

Shiftin’, Piecin’, Spinnin’ Warp, Weft and Twine,

Tae feed and claed my Bairnie affa ten & nine

Oh, dear me, the World is ill-divided,

Them that work the hardest are aye the least provided,

I maun bide contented, dark days or fine,

There’s no much pleasure living affa 10/9

Linen: Maberly & Co. of Aberdeen had 200 Power-Looms erected for Linen Manufacture. The Power-Loom has been in uninterrupted use in the Broadford Factory, Aberdeen, and that Firm may be credited with being the effective Introducers of Power-loom Weaving in the Linen Trade.

Flax Manufacture.

The Manufacture of Flax is carried on to a considerable extent in Aberdeen by 3-Firms, all of which carry on the several Branches of Spinning, Bleaching and the Manufacture of Linen of every quality, from the coarsest Floor-cloth & Osnaburghs, to the finest Shirting, and one of the Houses is extensively engaged in the manufacture of Sewing Thread.

In the closing years of the 20thC, Richards again experienced Financial difficulties with severe Job Losses. In January 2002 Richards plc went into Receivership, leading to the eventual Cosure of the Broadford Works. The History of Broadford Works reflects the general History of the Textile Industry, which was liable to severe fluctuations with the rise & fall of Profits and demand through the 19th & 20thCs.

A Sundial dated 1692 on its rounded face and the letters ‘WI‘ & ‘LS‘ on its Squared Side. It was reportedly found at the Site of Broadford’s Flax Mill during Demolition Work in the 1st few years of the 20thC. Much rebuilding Work has been done in that area in the years 1901-1912 with a large House & Garden being demolished during that Period. The Sundial is 0.6M high and 0.38M wide, with a 5-sq cm Socket in the Base.

To Frederic Holland, Esq, Managing Partner of the Firm of Richards & Co, Broadford & Rubislaw Works, – This Volume (Willy Waly) is respectfully dedicated. (c.1870 Local Poet James Ogg)

Respected Sir, no mighty Bard am I,

Nor do I dream to e’er be known as such;

True, wild Ambition bids my hopes soar high;

But Wisdom tells me not to hope for much.

I hope, by turns, to make my Readers sigh

And smile, according to the wire I touch ;

In short, my Bookie, Sir, may have the power

To take the tedium from a leisure hour.

I’m not conversant with the flowery way

In which great Poets write their Dedications;

Still, I’m entitled to my humble say,

As well as those who utter Grand Orations.

“E’en kits will mew & dogs will have their day,”

As Shakespeare says in one of his creations;

All I can say, but tends to this effect:-

Accept this Token of a Bard’s respect

I fondly hope my homely little Craft,

When fairly Launched, may Weather out the Gale

’Tis firmly fitted up, both ’Fore & Aft;

The Riggers too, have done their duty well.

Still, stormy Critics (aften somewhat daft)

May tear to shreds my unassuming Sail.

Well, well, though hard to whip a wayward child,

’Tis better that than have our children spoiled.

If there is aught upon these simple Pages

Thou likest not, then let me know that I

May Raze it out, ere they by future ages

Are read & branded with a withering – Fie!

“Oh!” cries the Linnet from the leafy Hedges,

“That I could, like the Laverock, reach the Sky!”

Thus I, sometimes, to higher strains aspire

Than soundeth nat’ral on my lowly Lyre.

But why prolong this jingling, simple scrawl,

When what’s to say, can be so quickly said?

Long Life & Happiness to thee, and all

Connected with thee; and success to Trade.

And, Sir, believe me that – whate’er befall

This puny Work – ere I retire to Bed,

Each Night I’ll pray sincerely, fond & fervent,

For thy Prosperity.

Your humble Servant, (James Ogg)

James Ogg, Aspiring Local Poet – Born in Banchory-Ternan in 1849 (now Banchory), Kincardine whose 2-Poem Collections Willy Waly (and other Poems 1873) & Glints I’ The Gloamin (Songs & Poems 1891 – Hard Cover) were written during his toils & reflections on life 1st as a Grocer’s Boy, then as an Employee at the Rubislaw Bleachfields & finally in an Aberdeen Sawmill). His Family moved to Aberdeen when he was but 4-yrs-old no doubt for Employment Prospects & appear to have Settled in Lofty Tenement Attic Accommodation in the Northfield area above Jacks Brae in Gilcomston. He had but 1-year at School and his further Education came from his mother a woman well Versed in Songs & Folklore. He was largely self-Educated and was more than familiar with deprivation and the torments of life in the Poorer parts of the Town. He illustrates in Local Dialect life’s quandaries over Love, Religion, the Perils of John Barlycorn & the early Deaths of Infants amid the Pestilence of his Location. While struggling with his own Expressions he held his Elder brother (also a Sawyer) in high Esteem as in his Ode ‘Oor Willie – (wis the Best)’. His Poems were Published in 1873 & 1891 by Aberdeen Free Press. His Employer Frederic Holland may have Financed the 1st Publication hence the above Verses of Gratitude.

Banchory-Ternan, a Parish partly in Aberdeenshire, but chiefly in Kincardineshire, containing the Village of Banchory, Upper Banchory, or Arbeadie, which stands at 166-ft above Sea-level, on the Northern Bank of the Dee

When the Linen is Manufactured here a quantity of it is taken to the Bleachfield at Rubislaw where it is made ready for the Market. Here also are large Vitriol Works and is all carried on by the Proprietors Richards & Co.

1883 Newspaper Article: Elspet was born in 1863 in Aberdeen. In 1881, she Resided at 37 Ann Street (nr Boadford’s Works) with her sister Lilly who was a Flax Mill Worker & her mother Isabella who was a Housekeeper & born in Ireland. 3-yrs later, on 5th January 1883, at 8-am, she was involved in a terrible Accident in the Carding Room. Playfully hiding behind one of the Carding Machines from her Colleagues, her right-arm was caught in the Machine & was ripped from her Shoulder. She was taken to the Infirmary but the Report stated there was very little hope that she would recover. She was 20-yrs-old at the time of the Accident. 8-yrs later, the 1891 Census indicated she was Alive & her stated Occupation was a Former Flax Mill Worker. Under the Heading “Infirmity,” One Arm was recorded. Her mother Isabella’s Occupation became an Annuitant. 10-yrs later, in 1901, Elspet still resided with her mother now at 36-Spital, both as Annuitants. She was Single & 38-yrs-old.