Composite Built

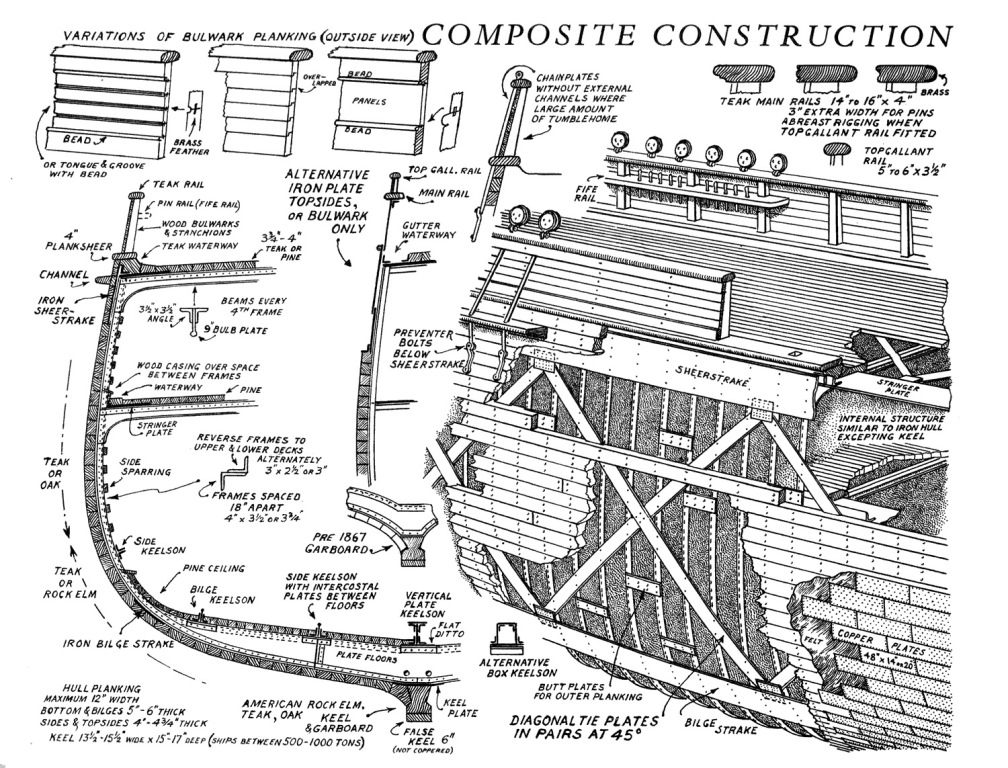

While Iron ships were inexorably superseding wooden ones, and supplies of good timber were becoming more difficult to obtain, there appeared on the scene a compromise which for a brief period was to produce the finest Tea Clippers ever built. These were the Composite Ships, which had a basic Skeleton of Iron covered by a Wooden Skin.

Many combinations of Iron with Wood Skin structure had been tried in the early part of the 19thC; also Iron Beam Knees, then Iron Beams, and next Iron Beams & Iron Upper Frames, but all with Wooden Skins which could also take the Copper Sheathing so much in favour for Speed as Barnacles did not cling to the Sheathing. It was this latter fact which provided some Shipowners with an excuse not to go all out for an Iron Hull, which of course could not take Copper Sheathing.

Speed of Building & Cost also often influenced the decision. Those Shipbuilders whose Yards could not be economically converted to build complete Iron Hulls were also glad to take up the challenge. For a few decades, Copper Sheathing was all the rage; but when Steel Hulls came into use in the 1800s, Copper could no longer be employed because it hastened corrosion of the Steel. Steel alone was impervious to worms but susceptible to Slime, Algae & Barnacles. Paints which was toxic to such growths were then developed for underwater and semi-exposed areas.

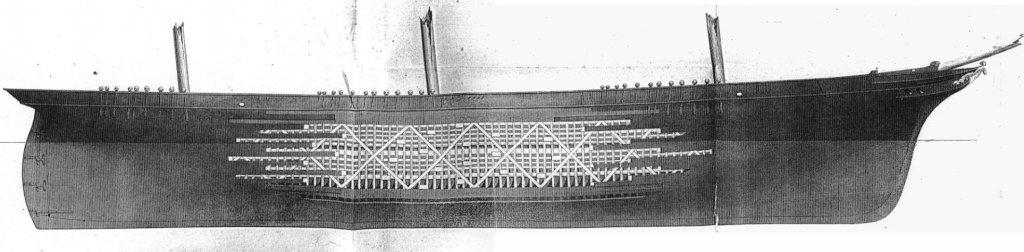

The Baring Brothers Archive – Marine Designer’s drawings in pen & ink, marked W. Rennie, of a Composite Clipper Ship viz – the Norman Court.

Scale: ¼−in. to 1-ft; with a list of principal dimensions. The drawings are:

Sheer Elevation, Body Plan & ½−Breadth Plan. Endorsed: Norman Court 5. c.1869:

Naval Architect’s Drawings in black & red inks, with a watercolour wash of Midship Section of Clipper Ship Norman Court. Scale: 3/8th-in to 1-ft.

No date: Naval Architect’s Drawing in black & red inks, showing a plan of Cabin & Living Accommodation aft for an unspecified Ship (Norman Court?); showing positions of furniture. Scale not stated – Marked ‘W T Young, 40 Penny Fields, Poplar, London, E’

Payments include: to A & J Inglis for the Ship herself; to William Rennie for the Builder’s Model; to Mr Wyon for drawing Heraldic Arms; to Captain Shewan for Salary & Travelling Expenses; for Provisions and other Expenses in Glasgow; for Towage & Pilotage on the Voyage from Glasgow to London.

Naval Architecture was still being taught at Poplar Technical College in 1962.

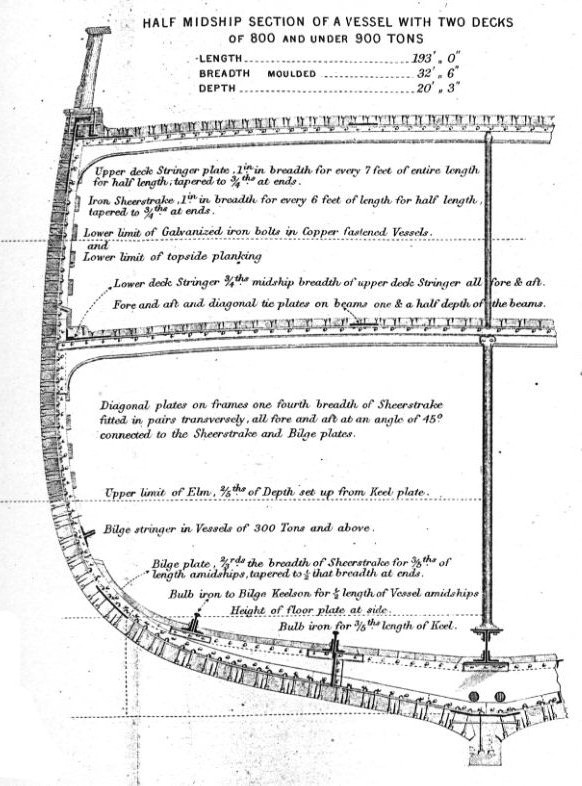

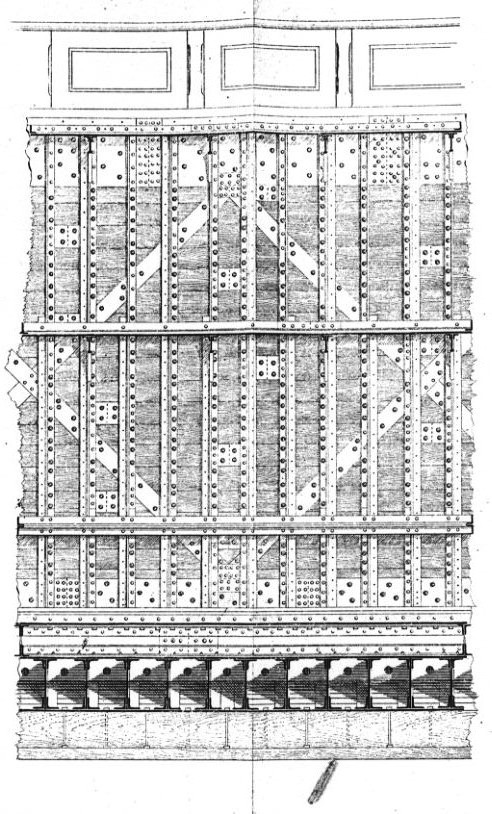

Midship Section

Marine Designer’s Drawings in black & red inks, with a watercolour wash of Midship Section of Clipper Ship Norman Court.

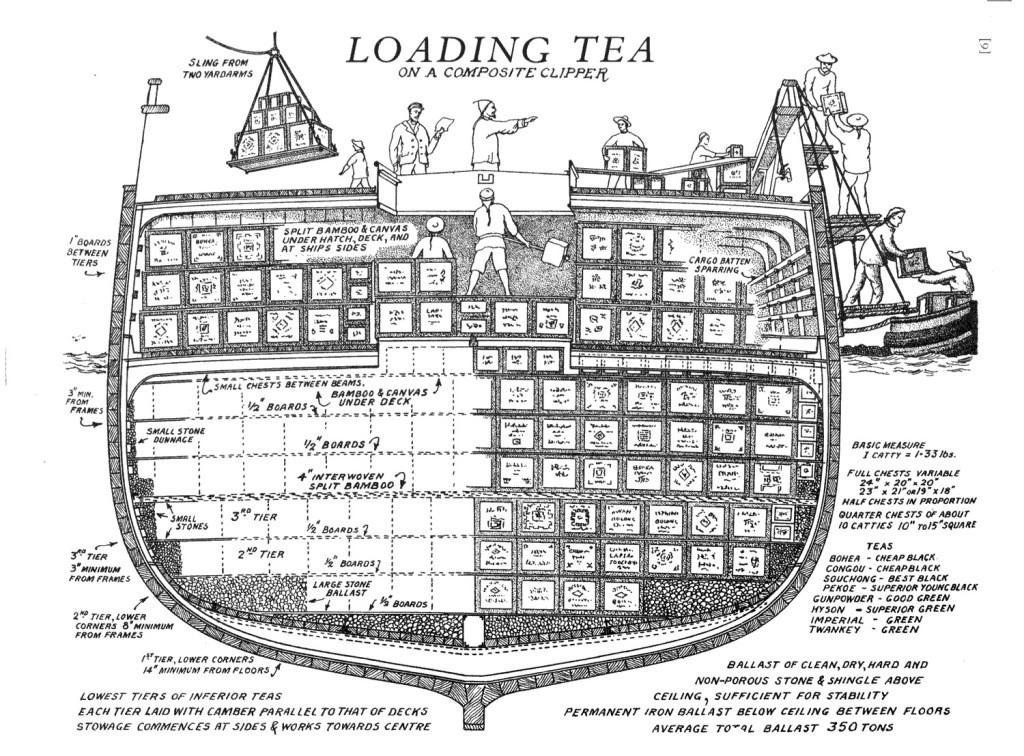

A few Composite Clippers were being built in 1869 and continued with the earlier ones to struggle for inferior Tea Cargoes, which they carried to the American Shores, Australia, and at intervals to England, until about 1886, the ‘Halloween’ being the last. Their life was not over, however, and with the addition of the new Iron Clipper the Wool & Emigrant Trades to Australia & New Zealand still proved economical enough to keep them going, and on occasions to outpace their Propeller-driven rivals, even with rigs much reduced from those carried during the peak of the Tea Trade. One or 2 managed to earn a living into the next Century, the Cutty Sark is an obvious example.

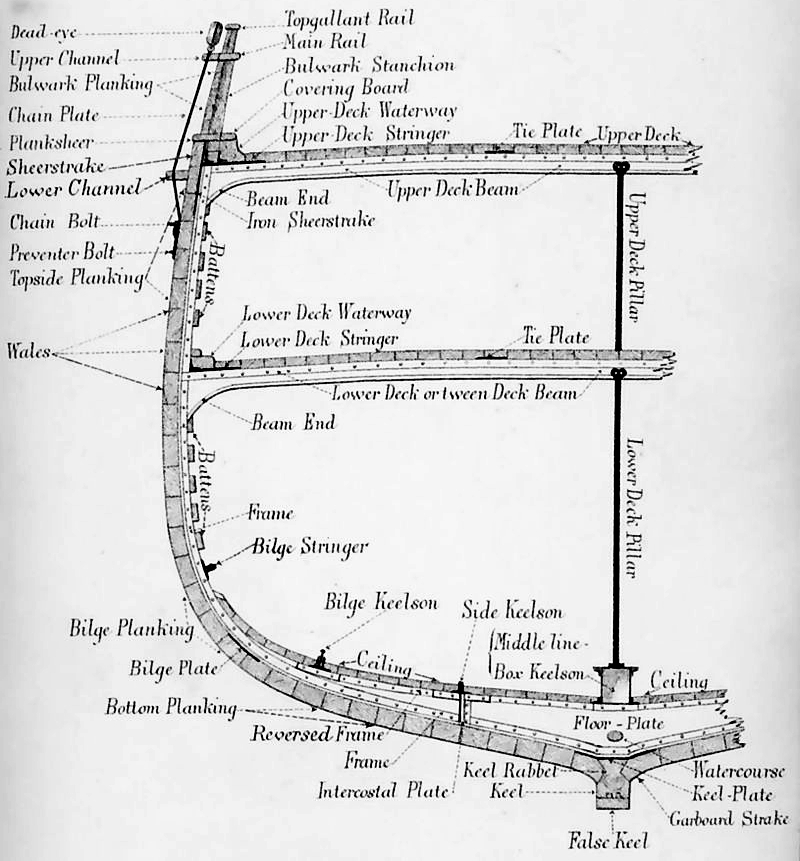

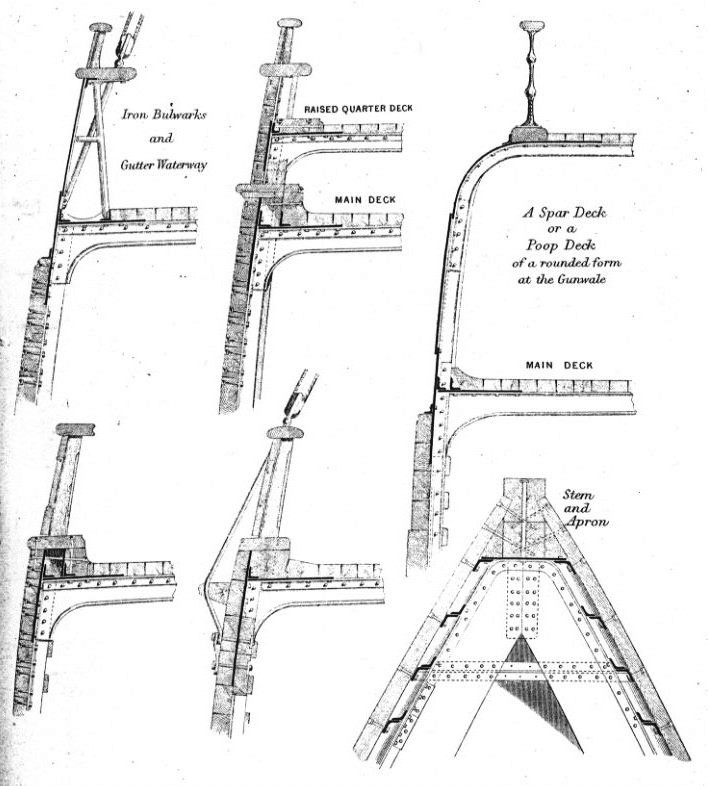

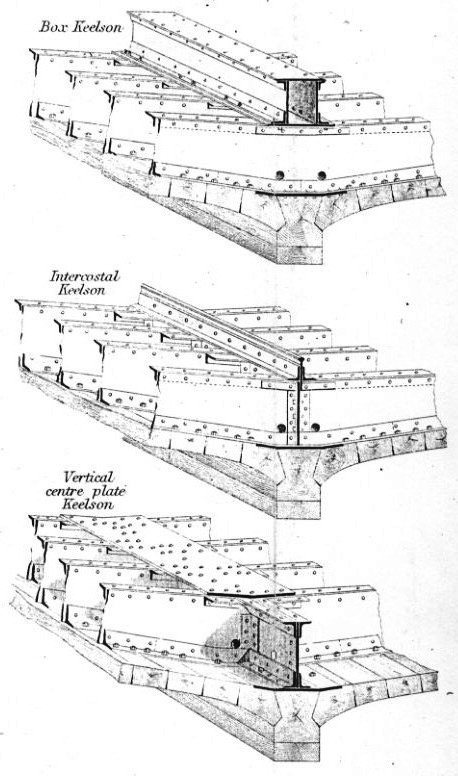

Bracing, Stringers & Frames

In all these systems the Keel, Stem, Sternpost, and usually the Waterways were of wood, with the Side-framing, Floors, Keelsons, Stringers, Sheerstrake, Deck Beams, Diagonal Straps & Deck Tie Plates of Iron. The greatest problem was to avoid contact between the Copper Sheathing and any Ferrous metal where saltwater could touch both and set up an electrolytic action. For this reason, Lloyd’s suggested that the bolt fastenings of the external planking be made of Brass or Copper. If of Iron, preferably Galvanized, the external heads had to be sunk below the face of the planks and covered with a wooden dowel or cement mix and in addition, covered with a minimum of 1¼-in. of wood Sheathing on top of hair Felt. These latter measures could considerably alter the Lines of the Hull and the Displacement. Internally, with the Jordan System, the bolts were tightened up directly on the Iron Frames, but if of Copper or Brass, they were insulated to some extent by a coating of gutta-percha or red oxide paint. Despite the fact that Bilge or condensed water could make contact with these fastenings, they seem to have successfully stood the test, like those on the existing Cutty Sark bear testimony.