Harper & Company 1856 ~

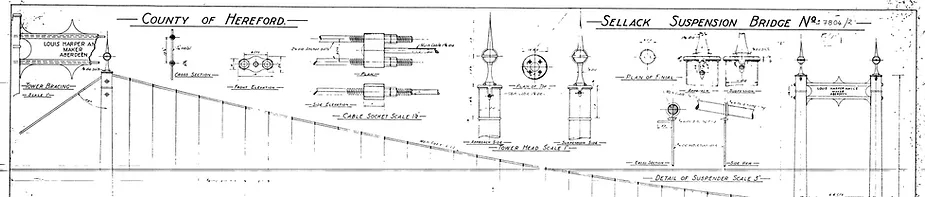

Harper’s developed an important line of Business in Wire Fencing & Cast-Iron Fencing Posts. This led them to develop Iron Suspension Footbridges, and in a period of over 30-yrs they produced many such Bridges for the UK & Overseas. An excellent History of the Company, with the main focus on their Suspension Bridges, was Published by Douglas Harper in 2015

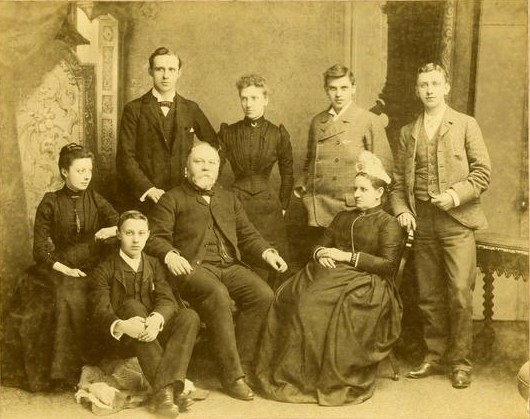

Parked outside Seafield House, the Home of John Harper

1901 Car – John & Hugh Harper were Engineers who Founded the Business of Harper & Co of Aberdeen. (Inset) The proud Harper Family in the 110th Motor Car to be registered in Aberdeen. Parked outside Seafield House, Seafield Road, Mannofield, the home of John Harper. John is the man seated in the front, smoking a Cigar. Directly behind him with the large Beard is his brother Hugh. These 2 men were responsible for setting up one of Aberdeen’s best-known Engineering Businesses.

They were brought up in Turriff, at the Mill of Laithers. About 1857 (when they were in their 20s) they opened an Iron Gate & Wire Manufacturing Business in Aberdeen. Literally, their Wire was to be found throughout the North East of Scotland: supplying Wire with Cast-iron Posts & Iron Gates to large Estates such as Glentanar & the Great North of Scotland Railway. From this, the Brothers went on to manufacture Suspension Bridges, set up their own Foundry & Machine Shops. Later John Harper moved into the Manufacture of Suspension Bridges, Engines and other Machinery. Originally at Albion Iron Works, Albion Street, (from Justice Street to the Links). They began to specialise in the Manufacture of Power Transmission Systems for Mills. John Harper died in 1906 & Hugh in 1912.

John Harper left his Parents’ Farm near Turriff in Aberdeenshire around the age of 9 and found Employment as a Market Gardener before moving down to Edinburgh with his brother Hugh, where they became Wire Fencers. This continued in Glasgow and in 1856 they returned to Aberdeen to set up their own Business as Fencers & Gate Manufacturers. Before long they had established a Foundry. In 1863, aged 30, John Harper Registered a Patent ‘device for straining wire’, which was crucial to the development of Bridge Building. The Wire was wound up within the Post using a Crank Tool rather like an ‘Allen’ key. Once the desired Tension was generated, the Spindle was locked by the insertion of a Peg into the opposing notches, one on the Spindle and the other on the Casing. This was similar to the ‘key’ required to fix a wheel to its axle after the creation of slots in both components – a Technique central to Harper’s Main Business of supplying Power Drive Machinery to Aberdeen’s Mills. It is interesting that the notches on the spindle are at 90° intervals (4) while those on the Casing are at 120° intervals (3). This means that the rotation of only 30° will allow another opposing pair to accept the locking Key or Peg. The 1871 Bridges bore the Harpers Patent Cable Tensioners that had been developed from the Fence Strainer – as did others until the end of the century.

Harper & Co Engineers, Ironfounders, Machine Makers, Millwrights, Wire Fencing, Iron Gate & Wire Fence Manufacturers, Railway Fence & Telegraph Wire Contractors, Ornamental Wire Workers, General Blacksmiths & Agricultural Implement Makers,

Albion Iron Works, Albion Street/Fish Street, (1856 until c.1890)Harper’s Limited, Founders, Engineers, Millwrights, Blacksmiths & Storemen

New Works, Craiginches (c.1892)

Warehouse, Market Buildings, 20 Hadden Street

John Harper, Sr, Seafield House, Mayfield Gardens, Seafield Road, Mannofield. Iron & Wire Merchant

Hugh Harper, (of Harper & Co), Thorn Villa, Seafield

John Harper Jr, (of Harper & Co), 34 Osborne Place, AB25 2DA

John Harper Jr, Managing Director (Harper’s Limited), h.Heathpark, Maryculter.

Louis Harper, AMICE (of Harper & Sutherland, 115 Union Street) h.58 Gladstone Place, Harlaw AB10 6XA

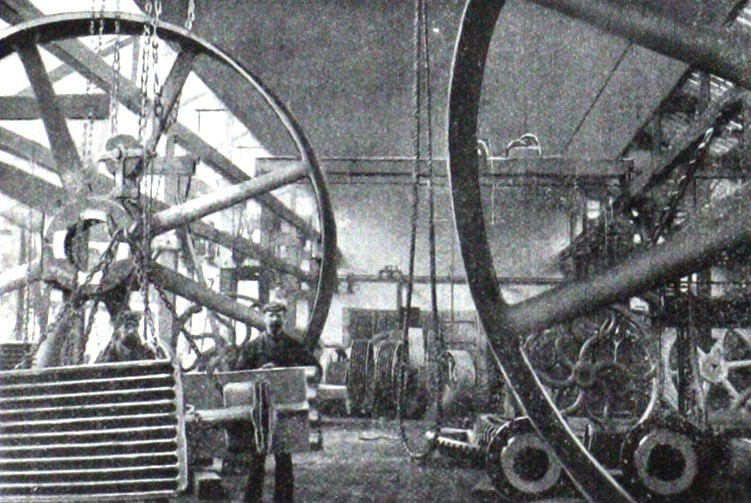

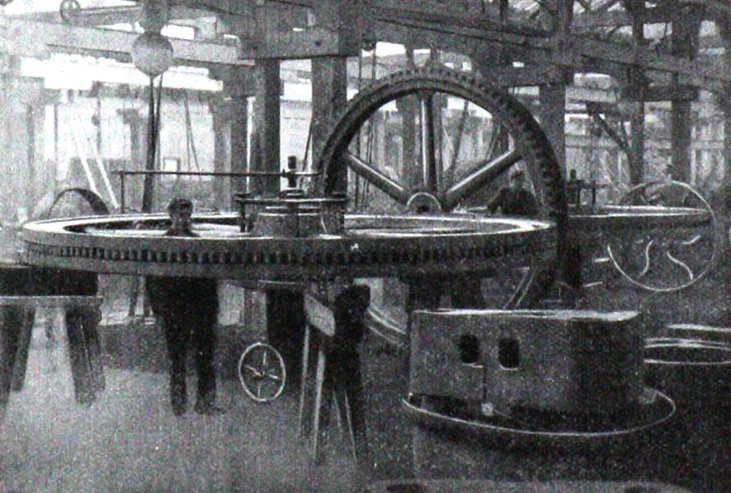

1892 The Craiginches Iron Works were erected on the South Bank of the Dee to meet the increasing demand for Rope & Belt Pulleys & Fly-wheels, Tooth-gearing, Steel Shafting, Bearings & their supporting fixings & generally, all accessories required for the Transmission of Power.

1895 Advert. Accessories for the Transmission of Power. Belt & Rope Pulleys, Gear Wheels, Shafting etc.

Harper Bridges: The Harpers were involved in the construction of light wire Suspension Bridges from about 1865 until 1924. Initially, they Designed & Built & latterly only Designed. John Harper, originally a Fencer, ‘knew how to Tension Wire’. In 1870 he was Building Bridges up to 300-ft Span using the same Technology, using a newly available material possibly for the 1st time – Steel Wire Rope – in a way that provided Stability & allowed a Lightweight Structure in place of the heavy Cast-Iron Chains & massive Towers of the 1820s such as the Wellington Bridge at Craiglug (1830).

In 1871 Mr Harper Foundry Owner & Suspension Bridge Designer offered to erect a Foot-bridge across the Diverted River Dee Channel at his own sole Risk & Expense, in return for a Pontage (Toll) of a ½d for every person who passed over the Bridge within the 1st-yr after it was completed. It was feared that the Structure would be too Slight & little favour was shown for this Proposal. In the same year, Mr Harper repeated his Offer, proposing to erect a Bridge fit to carry as many people as could find standing Room upon it, for a pontage extending over 2-yrs or amounting to £1260; but nothing came either of these proposals.

Louis Harper AIMCE was born on 6th June 1868, the son of John Harper, a Native of Turriff & his 2nd wife Margaret Ross. Louis attended Nelson College at Lee in Kent from 1880 until about 1881 & Aberdeen Gammar School from 1881-1883. He served his Articles from 1883-1887 with Jenkins & Marr who were Architects as well as Civil Engineers. In the latter year, he joined Harpers Limited as Manager of the Bridge Department. At this time the Business was managed by his older half-brother John who has taken over after his Father retired, though at this time the latter still acted in an Advisory role. 2-yrs later in 1889 Louis commenced Practice on his own Account at 115 Union Street as Architect & Civil Engineer, his 1st known work being Stores for Harpers Ltd.

The 7th Baronet of Monymusk, Sir Archibald Grant, was one of several Local Estate Owners who asked Harper & Co to Bridge the River Don in Aberdeenshire, in an area known locally as Paradise. The Bridge 0f 1879 is seen here looking North from the Left Bank, Upstream towards the Hill of Bennachie. The Main Cables pass through Timber Masts to reach the corresponding Tensioner Boxes mounted on the Bankside of the Masts, while the Anchor Cables pass through the Post at about the same Level to reach their Tensioners in the River aspect of the Mast. The Bridge initially had Timber Masts, probably constructed of Larch from the Estate, but at some Stage these were replaced by RSJ-shaped Steel Beams to which Harper Finials were added. The Design of the Finials indicates that this is likely to have taken place in the late 1890s. The Bridge continued in Operation until around 1970, when the Ord Watermill finally closed. It then gradually fell into Disrepair. Each Hogmanay, normally sober & upright Members of the Community could be seen making their Annual Crossing on the remains of the Cables, until the Bridge, now Derelict, was removed by Sir Archibald Grant in 2005. One of the Tension Boxes features in the Technical Section & presently forms part of the Harper Archive at the Aberdeen Art Gallery and Museums

Burnhervie Bridge – River Don – Completed c.1880. “The Original Bridge was Built by Harper & Co, Aberdeen, around 1880 & its Timber Pylons were replaced with Cast-iron Ones. In 1979 when overloaded during a Raft Race a Bank Stay Cable failed & a major re-Build was undertaken by the Local Authority. This Version was similar to its predecessor but was replaced in 2005 by a Cable-stayed Bridge.”

Louis Harper was Elected an Associate Member of the Institute of Civil Engineers on 5th December 1893. On Christmas Day 1895 Louis married Alice Edwards. They had 5-children, though none became Architects. At the beginning of 1896, Harper took into Partnership George Sutherland who was then in Practice in Elgin but had received at least one Commission in Aberdeen. The Harper & Sutherland Partnership lasted until about 1899 or 1900 when Sutherland withdrew. Harper remained in Practice at the same address but transferred his Business to Seafield, Aberdeen, his Home Address, in about 1903. When in Partnership with Harper, Sutherland’s one major Commission was a Large Block in Bridge Street, the remainder being Speculative Housing, some of it for himself. Sutherland subsequently formed 2 other Partnerships with James M Pirie in 1902 and after this was dissolved from 1907 with Clement George. Despite the Partnership with Sutherland, Harper was Principally an Engineer in the 1890s & was responsible for a large number of Bridges built to his father’s basic Design, mainly for Private Estates initially but later expanding to Public Work & in the 1890s for an increasing number for Foreign Countries as far afield as Nepal. A Bridge for the Great Northern Railway at Lincoln & Bridges over the Rover Bandon, Co Cork, Ireland, over the Feugh at Banchory * over the Carron at Falkirk. He was involved with the Design & Construction of Bridges over the River Nairn, over the Dee at Chester, Darwin Harbour in the Falkland Islands & Tees at Crathorne, Yorkshire.

After 1905 only 1-Bridge is recorded. About 1909, came the collaboration with James Abernethy & Co, Aberdeen who Manufactured Rail & Road Bridges of short spanned Truss Design. With Louis Harper, their Suspended Rigid Truss Bridges over the Aberdeenshire Dee & at Victoria Bridge Aberlour on the Spey were Built. Louis Harper died on 26th January 1940, though the Business appears to have continued after that date.

Lincoln Bridge – a Lattice style Footbridge with Brick Piers & Wooden Walkway, constructed (along with 2-others) by Great Northern Railway to carry an existing right of way over the New Railway. The Bridge was modified in 1960 to give extra height following the proposal to Electrify the Line (which never happened). A Survey of the Bridge was carried out in 2002 prior to its proposed demolition

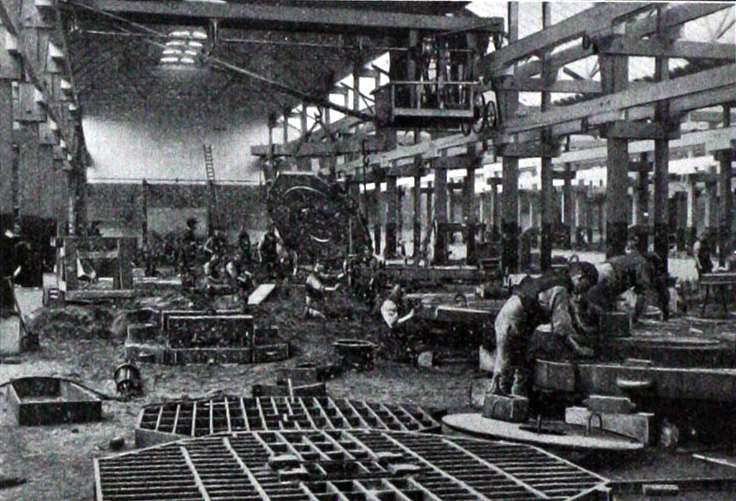

Louis Harper, Architect & Engineer designed the Craiginches Ironworks for his father, John, in 1892 in an Area that is now known as East Tullos Industrial Estate. These Works, situated on the Southside of the River Dee & about 11-miles from the Joint Passenger Station of the 3-No. Railways entering the City were erected in 1892 to meet the increasing demand for the various Products they Specialised in.

The Harpers Factory had 5 Bays altogether (35-ft, 25-ft & 3-Bays of 18-ft wide) all of which were 260-ft long, the 2 larger being furnished with 3-Electric Travelling-Cranes, 2 of 20-Tons & 1 of 8-Tons carrying power.

Harpers Ltd (which was the 1st Aberdeen Factory to install Electric light). Manufacturing included Rope & Belt Pulleys, Flywheels, Toothed gearing & Bearings, high-class Steel shafting & generally, all accessories required for the Transmission of Power. The Premises were Lit by 55-Arc-lamps, aggregating 750,000 Lux & are served by 28-Travelling Cranes on 2-miles of overhead Rails & 28-Electric Motors with a Roof area of 3-acres.

In this Department are 2-Cupolas melting 9 & 6-Tons of Iron per hr respectively & conveniently arranged for rapid manipulation are numerous Gear-wheel Moulding Machines & Rope-pulley Grooving Machines capable of an Output of 100-Tons of Castings per week.

The ‘Turnery‘ (Machine Tool Shop) which has an area similar to the Foundry, is connected with the latter by Bogie Rails for the rapid Transport of Castings to Tooling Operations and is equipped with special Shafting Lathes, Milling Machines, Keyway Slotters, Shaft key-Grooving Machines, modern Boring & Turning Mills, etc, all driven off 4-Lines of Shafting, each divided & operated by 2-Electric Motors stationed in the Bay Divisions, thus giving clear space for the many Overhead Travellers.

These Works, complete with well-arranged Patternmakers’ & Stores Departments, are connected by a Siding to the Caledonian Railway Co‘s Main Line & were erected, after long experience in the different Branches of the Trade handled, for the rapid & economic Output of the Specialities above indicated. They are conveniently situated for the Transit of Raw Materials & Finished Work, by Water as well as by Rail. The number of men Employed is about 400.

The adjacent Caledonian Railway connection allowed the Import of Pig-iron & the Export of Finished Castings. Harpers Ltd also produced light Iron Suspension Bridges Designed by John Harper. The Harpers main Business was supplying Power Drive Machinery to Aberdeen’s many Industrial Mills.

Harper & Co, Blacksmiths, Wire Workers, Wire Mattress Makers, Iron & Wire Merchants & Contractors, Agricultural Implement Makers & Agents; Works, Hadden’s Mills, Green; Warehouse, Market Buildings, 20-Hadden Street. c.1905/7