Granite Masons

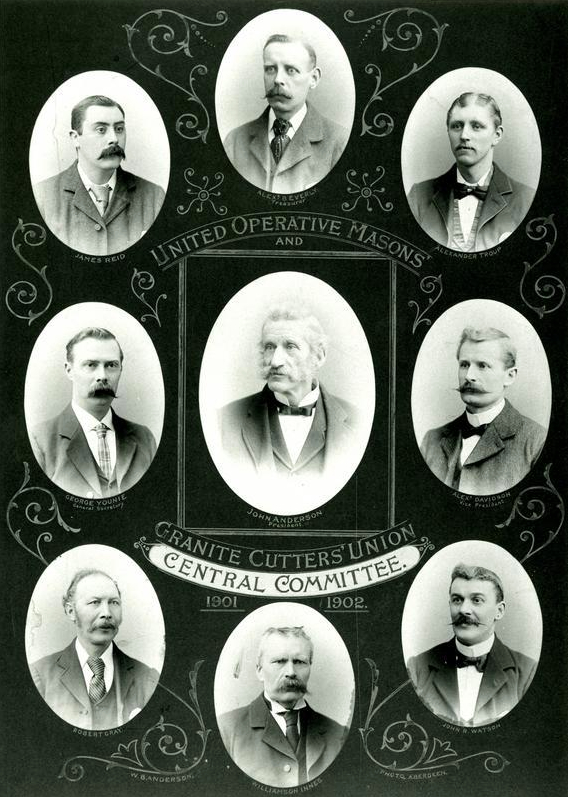

Founded as the Aberdeen Operative Masons & Stonecutters Society in 1888, it changed its name in 1892 to the United Operative Masons & Granite Cutters’ Union. By 1894 it had nearly 2000 Members – nearly all those Eligible to join. Its Agreement with the Aberdeen Granite Association Guaranteed that only Members of the Union would be Employed, and it continued in Operation until 1919. In 1920, the United Operative Masons & Granite Cutters’ Union Amalgamated with several related Unions to form the Building & Monumental Workers’ Association of Scotland. This later Amalgamated with the Amalgamated Union of Building Trade Workers in 1942.

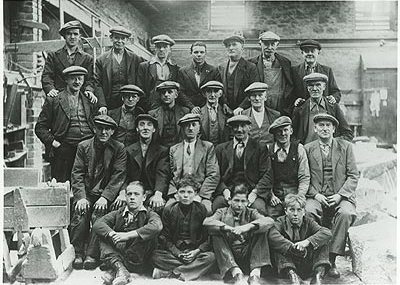

Men of Granite – A true acknowledgement of Granite’s contribution to the City is not possible without acknowledging the Granite Workers whose skills & labour established & sustained the Quarrying & Manufacturing Industries. This Group of Masons was photographed at A A Brown’s Granite Yard in Aberdeen in 1940. The Granite Business of A A Brown was owned by Archibald Abel Brown (1856-1917). He married Jane M Stewart (daughter of James Stewart Snr, niece of James Garden & Mary Stuart). A A Brown’s Granite Business was based at St Nicholas Granite Works, Advocates Road, (Kings Crescent to King Street, nr the Militia Barracks) from at least 1915 to 1940. In the 3rd row from the top, 4th left is Willie Simpson who was Yard Foreman. Mr Simpson, who was a skilled Carver, was given this Status when he was found to be suffering from Silicosis. Some reward eh – drowning in fresh air as a result of perfecting a skill by creating the Stone dust that incapacitated you and perhaps your family. At an early Apprentice age, breathed, ate and transported home to your relatives & family.

Louis Cruden was a Stonemason on my Paternal Family side and looked more like a living snowman during his working day and further hastened his own end by his willing addiction to Cigarettes. – Ach weel ye hae tae dee o’ summat! Tell that to the Apprentices in the Front Row who could not foresee their own future ‘behind’ them.

OS Map 1867 of Spital Area showing Granite Yard

Stonecutters.

William Anderson, St Clair Street,

George Brewster, 150 West North Street,

Christie & Gordon, 36 Cotton Street,

John Craig, 12 Nelson Street,

Arthur Fraser, Nelson Street,

John Fraser & Son, North Broadford,

James Garden & Co, Gerrard Street,

David Glennie, 84 Gerrard Street,

Grant & Watt, Affleck Street,

James Grant & Son, Bon Accord Terrace,

James Hunter, 209 King Street,

James Hutcheon, King Street,

G L Jamieson, Crown Granite Works, North Charlotte Street,

William Keith, Jr, 187 King Street,

George Law, Guild Street,

John W Legge, South Bridge, Holburn Street,

William MacDonald, St Clair Street,

Milne & Wishart, 35 Charles Street,

Alexander Milne, 124 West North Street,

J & J Ogg, Wellington Road,

Alex Petrie, 71 Constitution Street,

J Petrie & Co, Clayhills, Wellington Road,

Alexander Robertson, Wellington Road,

George Skinner, Victoria Street South,

A & J Smith, Gilcomston Park,

John Taylor, Leadside,

Andrew Williamson, 20 Mounthooly

John Fyfe (Quarry Products) Ltd

John Fyfe 1830-1906 of Kenmay Quarry He invented both the Steam Derrick Crane and the Blondin (an Aerial Suspension Cableway with a Travelling Carrier able to lift up to 20-Tonnes of Stone from the Quarry’s Floor to the Quarry’s Edge). He found the inspiration for the Blondin from his observation of a simple Ropeway system slung across the River Dee, which carried the Mail to Abergeldie Castle. These 2 Inventions revolutionised the Nation’s Quarrying Industry and he 1st used them in 1873. They were named after the famous French Tightrope Walker Charles Blondin (real name Jean Francois Gravelet) (1824-97). Blondin, later, gave a demonstration of his ‘Aerial Prowess’, in Aberdeen, on a lofty rope stretched across Golden Square.

Kemnay Quarries, were from 1858 Leased by John Fyfe, an Aberdonian; by 1880, 250 men employed with 7 Steam Cranes & 2 Blondins (Wire Lifts – his invention). Blocks 30ft long & 100-Tonnes in weight were produced in their heyday. Celebrated for supplying Holborn Viaduct in London. The Quarry was opened in 1830 by John Fyfe, and became fully Commercial in 1858. Kemnay Granite has been used in many famous Buildings & Structures, including:-

The London Cenotaph

Various Buildings on Princes Street, Edinburgh

The Forth Railway Bridge

John Fyfe, 72 Waterloo Quay

John Fyfe’s silver-grey Kemnay Granite, as it then went on to be more widely used in the construction of other Prestigious Buildings across the City, including the Citadel, Art Gallery, St Mary’s Cathedral, Northern Assurance Company Offices, HM Theatre, Palace & Grand Hotels and the exquisitely carved Granite Stonework Facade of Marischal College, not to mention the Thames Embankment, Piers, Docks, Viaducts, Lighthouses, Sea Defences & Bridges. Indeed, John Fyfe played a major part in giving Aberdeen its Silver City Title. The Portrait of Quarry-master John Fyfe by John Singer Sargent who, at the turn of the 20thC, was one of the Country’s finest Portrait painters. This Portrait was Commissioned for Mr Fyfe in 1902 by his Business Friends, Colleagues & Aberdeen Council Members. It was presented to him by his lifetime friend & rival Mr Manuelle. Lord Provost Mearns & former Lord Provost Fleming also paid tribute to Mr Fyfe’s worth, dwelling upon his generosity to the City, his pioneer work in the Granite Industry and the devotion of his whole life & energy to its development.

The Granite Supply Association Limited, of Aberdeen, was forced to curtail its Production & Employment owing to the scarcity of rough Granite Blocks of which they formerly imported 20,000-Tons to supplement home supplies; that much of this is required for Building work.

In 1899 the ‘Aberdeen Weekly Journal‘ reported on the installation of Electric Light at the Kittybrewster Granite Works: “An installation of the Electric Light has been fitted up in the Granite Works at Kittybrewster belonging to Mr James Knowles, and, on the occasion of the turning on of the light last night, a number of Gentlemen connected with the Trade met in the Yard for the purpose of witnessing the experiment, this being the 1st establishment of the kind into which the new illumination has been introduced. All expressed themselves highly satisfied with the success attained. There are 50 incandescent lamps & 6 arc lamps, and the installation has been carried out by Mr Riach, Foreman for Shirras, Laing, & Co., Ltd. The Gentlemen present at the inauguration last night were: Mr A Wilson, President of the Granite Association; Mr Lawson, of Macdonald Limited; Mr Garvie, of Mr Charles McDonald; Mr Arthur Taylor, Jute Street; Mr Archibald A Brown, Mr Cruickshank, Torry; Mr William Morgan, Portland Street; Mr J A Sangster, Engineer; & Mr A T Stewart, who has recently come from Edinburgh to fill the Post of Engineer in the Electrical Department of Shirras, Laing & Co.”

The Estates of James Knowles Granite Merchant, Kittybrewster Granite Works, Ashgrove Road, Aberdeen, and residing at No. 46 Clifton Road, Aberdeen, were Sequestrated on the 21st April 1909, by the Sheriff-Substitute of Aberdeen, Kincardine & Banff at Aberdeen. The 1st Deliverance is dated 21st April 1909. The Meeting to Elect the Trustee & Commissioners is to be held at 12 noon, on Wednesday the 5th day of May 1909, at the Imperial Hotel, Stirling Street, Aberdeen. A Composition may be offered at this Meeting; and to entitle Creditors to the 1st Dividend, their Oaths and Grounds of Debt must be Lodged on or before the 21st day of August 1909. All future Advertisements relating to this Sequestration will be published in the Edinburgh Gazette alone. Henry J Gray, Advocate, Aberdeen, Agent.

Messrs Simpson Brothers, Granite Merchants, Cotton Street, Aberdeen

Monumental Mason’s

William Edwards & Son (Granite Merchants) Ltd, whose Premises consisted of 2-Yards, No.s 3 & 4 Pittodrie Street. In August 1971 it acquired the Share Capital of Robert Crofts & Sons Ltd whose Yard in Pittodrie Street was adjacent to the former Edward‘s Yard on the Southside of the Street. It was to this area on the East side of King Street, bounded by Merkland Road East to the South and occupied mainly by Granite Firms since the 19thC.

Boddie & Wilson – William Boddie was born in 1838, and set up his Firm of Granite Merchants and Monumental Sculptors in Aberdeen in 1876, with Stone Cutter Alexander Wilson as a Partner, Trading as Boddie & Wilson. Their Workshop was at 37-St Clair Street (West North Street to King Street). At the time, Boddie lived at 57–John Street & Wilson at Orchard Bank Cottage, Old Aberdeen. The Partnership was short-lived, and in 1882, Boddie is listed on his own at 37–St Clair Street and living at 211–King Street. A decade later he expanded his Works to include Show-yards at 255-294 King Street and moved his home to 3–Roslin Terrace just North of the Railway. The Firm produced Granite Monuments for Cemeteries in & around Aberdeen, as well as Architectural Carving. Another aspect of their Work was the supply & carving of Pedestals for Public Monuments, their most important work of this Type being the Pedestal for the Statue of Sir William Ewart Gladstone in Glasgow’s George Square (1902). Designed by the Statue’s Sculptor, W H Thornycroft and originally Sited on the Eastside of the Square, the Pedestal was Built from the finest Axed Kemnay Granite. Unveiled on 11th October 1902, the Pedestal stands 13ft tall (3.96M), and its slightly curved sides are inset with Bronze Panels illustrating scenes from Gladstone’s Llife. Its front is adorned with a Bronze Shield with the Arms of Glasgow. Shortly after the Gladstone Commission was completed, Boddie entered into a Partnership with his son, Trading as W Boddie & Son, from 1903. William Boddie died on 24th April 1917, aged 79, and was buried in Aberdeen’s St Peter’s Cemetery, King Street, where his grave is marked by a tall, Granite Classical Monument carved with his entwined Initials. His Firm continued Trading until 1943, by which time Robert M Walker was its Manager

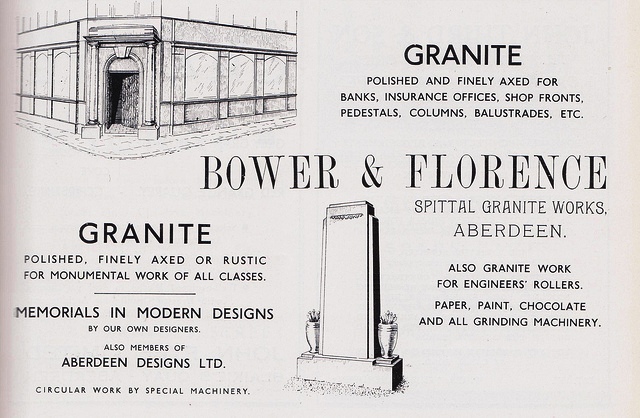

Bower & Florence

A Firm of Monumental Sculptors formed between James Haddon Bower (1831-1901) & John Florence (1837-92), at the Spital Granite Works in King’s Crescent. The Firm became one of the most important Granite Firms in Aberdeen, producing Architectural Work as well as Cemetery Monuments. Bower also Traded as a Lime & Manure Agent from 34–Marischal Street & 48–Market Street and lived at 18–Golden Square, whilst Florence operated independently as a Granite Polisher at Rose Acre, King’s Crescent. James Haddon Bower was born in Lochee, Forfarshire, and came to Aberdeen as the Manager of the North Eastern Railway Company’s Goods Department before forming his Partnership with Florence. He retired from the Partnership a few years later and was replaced by his son Haddon Anderson Bower (d. 1927); whilst he pursued his other interests in the City’s Businesses. Purchasing the Estate of Pitmurchie, near Torphins, he became greatly respected for his knowledge of affairs connected with Farm & Land Management, and for his promotion of the recycling of by-products from the Distilling Industry for Agricultural use as Feed Cake for animals, to prevent the Polluting of the Rivers.

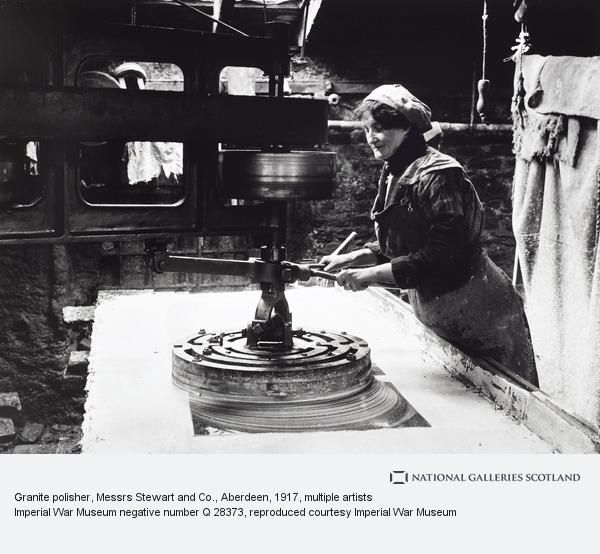

Around the years preceding WW1, John McLaren, a former Employee, returned to the Firm as Bower’s Partner. At the end of McLaren’s War Service, when 75% of the Firm’s Workforce was in Uniform, Bower petitioned the War Office to obtain McLaren’s early Discharge and return to the Works, in order to prepare for the imminent return to work of the Firm’s remaining men & others seeking to fill its Vacancies. The Firm was Purchased by McLaren after Bower’s death in 1927, became a Limited Company in 1947, and eventually Amalgamated with Stewart & Co Ltd, on Fraser Place in 1963, bringing to an end a Century of production at their King’s Crescent Workshops (nr Love Lane).

Spital Area Map

John Florence was Apprenticed as a Stonecutter in Aberdeen and had acquired a considerable knowledge of Building work by the time he became Bower’s Partner. He was also active in Local Politics as a Conservative, although he never gained Public Office. He died of Influenza. The Story of Bower & Florence was recorded & published by John McLaren (McLaren’s son) who became a Director of the Firm in 1947, in his Book 60-Years In An Aberdeen Granite Yard: The Craft & the Men, in 1987. This features a number of Photographs of the Firm’s Staff, including Haddon A Bower, John McLaren and their Masons, as well as Photographs of other Granite Firms at work.

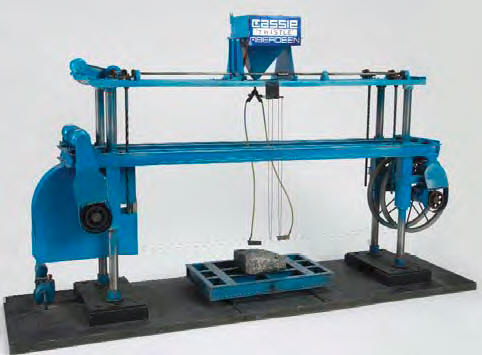

In an attempt to “modernise” Granite Production David Ruddiman Granite Merchant 1900-1965 and George Cassie & Son worked together on laying-out Plant in such a way that the Granite Business could manufacture wares in an efficient, fast & profitable manner. This entailed introduction of Diamond Circular Saws, new Wire Saws and straight-line Gang Saw as well as new Polishing Machines. In terms of the size of Aberdeen’s Granite Yards this was a major project. George Cassie & Son was, by the 1950s, the City’s major Manufacturer of Granite Working Machinery; eventually going into Liquidation c.1982.

George Cassie & Son

This type of Saw was designed to cut Granite. It was made in Aberdeen by George Cassie & Son Limited. Engineers & Blacksmiths, 500-King Street. (Eastside)

The Saw has an endless Wire Loop which is driven around the Wheels at each end of the Saw. The Wire was is fed down on to a Block of Granite but it is not the Wire that cuts the Stone. An abrasive (Carborundum) mixed with water was fed under the Wire. The revolving Wire rubbed the mixture against the Stone. In time this cut through the Granite making Slabs for Gravestones or for Buildings. The names they gave to their Machines ranged from Cairngorm, Piper, Eagle to Swallow the latter does not seem to have a particular Scottish connection. Aberdeen Museum has a Fine collection of Cassie Catalogues as well as many Engineering Drawings of the Company Products.

Granite Saws & Turning Lathes

Within recent years the Industry brought Saws into use with good effect. These Saws also have the Pendulum Motion. A Steel Blade, or Blades, with the aid of Diamond Grit – a coarser quality than that used for Polishing – and water, cuts the Block, thus giving 2-Clean Faces without the aid of hewing. If the Blocks are to have fine-Axed faces it may be necessary to go over them lightly with a Patent Axe; but if for Polishing, they can go right from the Saw into the Polishing Machines.

Circular work is now nearly all done by Turning Lathes, with a Circular Cutter working at an angle on both sides of the Stone. Boring is also done by Machinery, and holes through paint rollers, etc., are bored with the aid of a hollow Steel tube attached to a vertical revolving shaft. This Machine is also fed with diamond grit, and the Core which is left on the inside of the Drilling can be converted into small Columns, whereas, in the old method of dressing by hand, the whole centre was, of course, bored out.

Pittodrie Granite Turning Co. Pittodrie Road. – also at Wellington Road, Craiginches in 1970

Messrs. James Wright & Sons at the Royal Granite Works, 11-John Street. Aberdeen (From 133-George Street to Woolmanhill)

An Aberdeen based Granite Polisher & Monumental Sculptor, James Wright (1810-76) started as a Stone Cutter in the City’s John Street in 1838, when he formed a Partnership with James Petrie as Wright & Petrie, 1838-46. By 1851, he operated on his Own at the Polished Granite & Marble Works, John Street. In the 1870s, he received Letters Patent as a ‘Manufacturer to Her Majesty’, at 11-John Street, renaming his Yard as the Royal Granite Works. Wright was responsible for the Monuments in Glasgow’s Necropolis to the Engineer Peter MacGregor (1862) and the Aitken Family (1882). He also produced the plain, Granite Obelisk to Isabella Dalziel in Edinburgh’s Dean Cemetery (1858). He lived at 16 Shoe Lane, 1838, & 8 South Constitution Street, 1851. Wright died in 1876 and was buried in St Nicholas Churchyard. His sons William & A H Wright succeeded to the Firm and Traded as J Wright & Sons. The Firm survived until 1975, by which time it advertised itself as J Wright & Sons (Aberdeen) Ltd, Manufacturers of Polished Granite & Abrasives. William Wright went to Australia in the late 1800’s and set up a Granite Works in Victoria. He died here in Melbourne in 1921. Frank Wright, Granite Merchant (of J Wright & Sons, Royal Granite Works), 80 Queen’s Rd., & the Birches, Aboyne.

Royal Granite Works & The Dyer’s Well

Near the Upper End of the Lower Railway Tunnel, a Well 300-ft deep was found in the angle between Woolmanhill & John Street. This Well was purchased by James Wright Proprietor of Royal Granite Works a neighbouring Stone-cutting Yard, to get the use of the Water in his Trade. The Well also supplied water for a Steam-engine in a Tape Manufactory owned by Milne, Low, & Co, which was in Woolmanhill, between John Street & St Andrew Street. It also supplied water for Baths provided by the Company for the Workers.

Alexander H Wright, Granite Merchant, 90-Crown Street, h 53-Holburn Street.

In the 1930s a Granite Worker, Mr Pyper took his Family to London for a Period where he worked on Building the Bank of England Vaults, which are lined with unyielding Granite for Security.

Damage at Hogg & Company Granite Works in Regent Walk (King St to Golf Road)

9 High Explosive Bombs fell on the area around Regent Walk & King Street. One is noted as striking Hogg & Co, Glencoe Granite Yard.

William Edwards & Son (Granite Merchants) Ltd, whose premises consisted of 2 yards, No.s 3 & 4 Pittodrie Street.

Robert Crofts & Sons Ltd whose Yard in Pittodrie Street was adjacent to the former Edward’s Yard on the Southside of the Street. It was to this area on the Eastside of King Street, bounded by Merkland Road East to the South and occupied mainly by Granite Firms since the 19thC.

The hazards of working in the Granite Yards were also considerable, if not so likely to be Fatal. The noise & dust must have been considerable. One common accident was ‘Fires’ – fiery fragments of the steel tools, entering your Eye. This was exasperated by the practice of double berths where the men worked in 2-Rows in the Shed. Aberdeen’s great Local Historian, G M Fraser, started life in a Granite Yard before losing an Eye. He subsequently became a Journalist before finally becoming City Librarian for nearly 40-yrs. In the early 20thC Safety Goggles were introduced but the men wouldn’t wear them – they used gauze not Glass and so visibility was poor. They also caused the men to Sweat profusely. Little wonder that Granite Firms were among the Major Donators to the Aberdeen Ophthalmic Institution then in King Street.

The great & controversial fear among Granite Workers in the 20thC was Silicosis. Little understood in the 19thC its existence was denied by Employers into the 20thC. When it did begin to be studied it was found that Quarry Workers rarely suffered from it because they worked in the Open Air. In Granite Yards the men worked almost in the Open, in an Open-sided Shed. Around 1891 one of the leading Granite Employers, Charles Macdonald, was the 1st to build fully-enclosed Sheds for his men, in retrospect a Philanthropic Act to protect them from the Elements that may actually have unknowingly harmed the men. Even in the middle of the 20thC Granite Workers tell of leaving work looking as though they were covered in Snow. Sometimes they used the new Pneumatic Tools to blow the Dust off themselves, a practice ostensibly banned but still carried on even though it blew the Dust everywhere. The Work itself would have been long & tedious, it could take months for the primitive Mechanised Saws used in the mid-19thC to Saw through a large Block of Granite.

Even Polishers were not immune to Industrial Injuries apart from the Dust disease. Polisher Robert Taylor described how he caught his arm in a machine and broke it in 4 places – in his own words it looked like figure ‘S’! He joked that luckily the Infirmary was just around the corner from his Yard. Robert also described how there was Water everywhere since it was used to keep the Sawing Blades cool. It mixed with the ground down Granite to form a virtual Mud. For that reason, they wore wooden-soled Clogs with a steel rim & Sacks round their legs.

On Building Sites the various types of Masons broke & shaped the Stones to size. Unlike bricks, Granite Blocks didn’t arrive on Site ready to use. Attempts to shape the Stone at the Quarries had led to an Industrial Dispute at the time of the Building of Aberdeen Town House in the 1860s. Fred Cargill described his experience as one of the last Apprentices to serve his time on the last major Granite Housing Scheme in Aberdeen – Kincorth, Built in the years after WW2. Fred described being told on his 1st day that by night his hand would resemble a pound of raw mince but that he would soon stop that (missing the Puncheon or Chisel). Fred also described how in slack times Masons from the Yards came to work on Building Sites. In Fred’s words – on Site they were handless, though Technically all Masons and in the same Union.

It seems inconceivable to us today that into this harsh, dangerous environment, very young boys were brought to work in the 19thC. In memoirs written down much later, some men described starting work as young as 7–yrs, and even after the Factory Act, 10 was common. Sett-makers, in particular, employed their sons. They were virtually Self-employed & Employed their own Assistant, often their son, though too young to be Classed as an Apprentice. In 1953 William Henderson was the oldest employee at Kemnay Quarry. He was 76 and had started in the Quarry aged 10. In the Granite Yards, Boys were employed as Nippers doing anything they were asked. This often involved, if they were strong enough, pushing Wheelbarrows round the men collecting their Tools & Ferrying them to the Blacksmith for sharpening. Similar work was done at Quarries. Another job that boys might be given was feeding the Abrasive into the Saws which involved running between barely Guarded Machinery. There are instances of grown men catching their clothes in the Machinery so the danger to boys would have been even greater. The Granite men of old would surely envy today’s Working conditions where Machines do most of the Work. By the time Robert Taylor retired in the 1980s he could go to work in his suit since by that time he said he was simply pushing buttons. Robertson Granite’s new Yard opened just outside Aberdeen in 2017, is a world away from those we see in old black & white photographs.

Robert D Cruickshank & Co, Granite Merchants, Albyn Granite Works, South Esplanade East, Torry.

Aberdeenshire Epitaphs & Inscriptions

Historical, Biographical, Genealogical, & Antiquarian Notes, by John A Henderson, FSA